Fine, i'll admit, i miiiiiiiight be ever so slightly guilty of the whole "if all you have is a hammer, everything around you looks like a nail" thing, what with these nifty little one-cell charger & protection boards, but hey - at least it kinda validates(?) my "stockpiling" of laptop and phone batteries along the years. Now, i finally have the excuse to put some of them to good use and all that...

During my UK eBay browsing sessions a month or two (or seven?) back, i happened to come across a few listings of faulty wireless monitor sets (transmitter & bodypack-receiver) from this British music gear retailer. A bit of googling later, revealed to be straight rebadges of Takstar WPM-200 sets - nope, they hadn't even bothered changing the model number. The one thing they might've customized, though, are the radio frequency ranges / channels (since there are different regulations on different continents, and so on).

A couple weeks after i first saw them, i figured i'd pull the trigger, just for shits & giggles, if nothing else. Nice part was, they were all listed with "or best offer", so with the benefit of that, i managed to grab all three sets, including shipping, for just a bit under 70 bucks. This, in the context of the cheapest similar units from retailers like Thomann being north of 130$ each, while one brand new unit retails for (the equivalent of) 80$ or so.

After receiving them, i promptly proceeded to testing. Nice fellas though - unlike all those toy commercials from when we were young, with the dreaded "Batteries not included" disclaimers, these actually DID all come with a pair of AA's each (one of them Energizer, no less!). To my surprise though, despite one or two of the three having been listed as "no signal", they all seemed to work just fine. A tad noisy, perhaps, but definitely workable. I made sure to try all three receivers with all three transmitters, but as far as i could tell, they were all pretty much good to go.

Okie-dokes, on to the <ahem> "review" itself. Casing's cheapo ABS, going by the look and feel of it, but the LCD's nice enough. It doesn't really need to display much, so it's perfectly adequate for the purpose. Tactile switches are pretty loud, and perhaps a wee bit too stiff (ie. high-ish actuation force), but then again, since one shouldn't need to mess with them too often, they're plenty good; par for the course, if we also take the price into account.

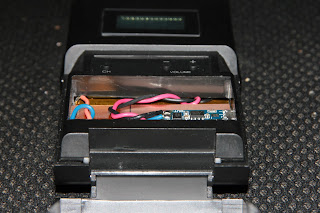

Other than that, the construction's neat enough, i suppose. The flip-open front half-cover (that reveals the volume up/down buttons, the channel selector and the battery compartment) has two pretty massive clips - the tips can do with a bit of sanding / rounding over, to make the opening a bit less risky / stressful for the cover itself. The belt-clip's made out of 1mm (or so) steel wire, plenty stiff for the job and appropriately shaped, and the casing's well reinforced where the ends of the clip hook into. And now, a look into the guts of'em...

Right off the bat, interestingly enough, one of the three receivers seems to be of a different "vintage" (read: revision) from the other two. Assuming the labels on the top boards (the LCD & button carriers, basically) are standard year-week datecodes, the odd one out is from week 34 of 2015, while the other two were made in 2016. That being said, let's get to a more structured and detailed rundown of what can be seen, identified and deciphered. Overlooking the obviously different layouts of the main boards, the RF and analog sections seem to be quite similar, if not identical.

|

| Newer revision |

|

| Older model |

|

| Newer revision, top board (LCD) removed |

Not much going on on the top board - disregarding minor layout differences between the two revisions, it's just the LCD, the three switches, the Holtek HT1621B LCD driver / controller and associated passives.

|

| Newer revision |

|

| Older model |

Right, the title of this also includes the term "li-po upgrade", doesn't it? Now, as i think we can all agree, using alkalines for these is, well... sub-optimal, shall we say? And Ni-MH rechargeables would need 1) to be bought, and 2) some form of dedicated charging - neither of which were particularily enchanting prospects, from where i'm standing. Enter the venerable(?) Nokia BV-5JW 1450mAh 5.5Wh lithium-polymer battery, as used in the N9 and Lumia 800 phones. From various sources, i've amassed a collection of at least 15 or so.

In their stock form, the BV-5JW cells were juuuust a few mm too long to fit sideways inside the casing. A few minutes later, following removal of the outside label and two tiny little Philips screws, the top and bottom plastic end-caps could be removed. Since the USB charging boards i was planning to use also include a DW01 single-cell monitoring & protection chip, the slim little PCB (that plays the same role in the stock form of the battery) was made somewhat redundant. The removal of that as well provided just enough length reduction, to get the battery to fit quite snugly enough into what used to be the 2xAA compartment. Well, after "carving" off the retaining slots that held the 2xAA contacts, anyway.

Speaking of carving, the top half of the casing required somewhat extensive... "remodelling". Namely, the bottom of the battery compartment needed to go, first of all, as well as the upper and lower walls (on the "length" axis of the receiver, in case it makes more sense), but not the end-walls on the left and right sides (width-wise). Depth-wise, due to the width of the battery (confused yet?), it needed to fit underneith the receiver PCB. As you can probably tell, the overall 3D fit ended up being pretty much borderline, in all three axes.

Next step, affixing the charging board. I opted to take the "quick & dirty" route (once more). For my purposes, it doesn't need to be pretty, just functional. Now, since i (had) envisioned the micro-USB connector of the charger, just "peeking out" through the receiver's casing, and the battery being the thickness it was, i also needed a bit of a spacer between the two (battery and charging board), so as to only need to carve a "window" into the top half of the casing. The simplest solution i could think of was a piece of bog-standard copper-clad PCB material. Simple? Check. Suitable for the purpose? Check. Available at hand? Check.

Just as in the first post on this blog (the M-Audio Fast Track mk1 mod), i decided to take the "stacked board" approach. I sliced off just enough of the USB end of the charger board, to get the connector to "overhang" enough to reach through the thickness of the casing wall, and after carving (or rather, scoring) out a few "islands" on the base-PCB so as not to short together things i shouldn't, i just soldered the charging board onto said PCB. I left the vast majority of the copper cladding as "circuit ground" (as opposed to "battery negative"), and just isolated the rest of the "terminals" of the charging board.

Just to be super-safe, i added a chamfered cut-out in the base-PCB for the negative terminal of the battery, and added a layer of Kapton tape in the area, to minimize the risk of it shorting to the circuit ground (ie. post-protection-MOSFETs). Also, i wrapped the cell itself in a layer of Kapton tape - better safe than sorry, and why risk melting / blowing up one of these? Yeah, they were cheap, but that's why they represent that much more value, especially after all the elbow-grease that went into these mods. The final touch was a nice wide strip of 3M 9087 tape along the whole length of the battery-PCB interface - that thing won't be going anywhere.

Since two fully charged series AA alkaline cells are around 3-3.2V, and they're considered fully discharged around 2-2.5V, a single lithium cell is considerably above those numbers (4.2V and 3V or so, respectively). As such, i preferred to err on the side of caution in this respect; as an added bonus to the approach i took was that the battery level indication on the LCD would remain accurate enough for the purpose. Enter the humble diode - yep, one plain ol' diode in series with the "B+" terminal of the battery / charging board. That's that little SOT23-packaged part barely visible and half in-the-air component between the "B+" and "OUT+" terminals of the charger board.

Since the voltage drop across that is in the order of 0.6-0.7V, that put the voltage reaching the receiver board pretty much right where i needed it to be: 4.2 - 0.6 = 3.6V when full, which is usually the specified maximum for 3.3V nominal supply digital circuitry; 3 - 0.6 = 2.4V when fully discharged. Don't you just love the simplest solutions to problems?

In order to minimize "wasted" power, i decided to increase the series resistors going to the LCD backlight, and the power indicator LED. I also upped the 1k resistors from the indicator LEDs on the charging board to 10k - i don't need those to light up anything meaningful, and they're plenty bright enough for what they need to do anyway, even at minuscule currents.

In part 2, the transmitter(s) will be dealt with. See you on the other side!..

does this affected the range of signal?

ReplyDeleteWhich range do you mean?

Delete1) The distance between transmitter and receiver?

2) The max amplitude of the signal at the input of the headphone amp?

3) The max amplitude signal at the headphone output?