And then i got thinking - it has the convenient mono/stereo switch on the front (to have both inputs in mono, or input 1 on the left and 2 on the right), a headphone output, doesn't need a specific power supply (it being bus-powered)... 😏

Rewinding to a couple years ago, i had collected several more-or-less dead laptop batteries from various sources, in the idea that the good cells would someday come in handy. About a month ago, remembering about several USB powerbank teardowns & analyses of bigclivedotcom over on YouTube, i figured i'd look for the DW01 single-cell protection chip (since the individual cells in laptop batteries are unprotected; the "smart battery" controller chip handles that). 👍

Since my "version" of choice is the British eBay, and i'm usually interested only in listings within Europe, some of the top results were these tiny little (up to) 1A single-cell Li-Ion chargers. They use a TP4056 linear charge controller chip; the boards are about 30x20mm in size (1-1/4 x 3/4in), charging current is adjustable via a single resistor, and include over-/under-voltage protection via a DW01 and an S-8205A dual MOSFET. These mini-USB-with-protection versions are called TE584; the only(?) other versions are only the charger (with associated passives) without the protection, named TE583 and TE585. The cute part is that they included footprints for both mini-USB and micro-USB on all boards, so if you're so inclined, you can replace the stock connector (which i intend to).

Now, back to the initial idea - given the simplicity and features of this little Fast Track, it seemed like a perfect candidate to use as a volume control and headphone amplifier for my in-ear monitors, when playing live on stage (you see, i'm also a drummer, among a few other things). Since it's bus-powered, it was quite obvious it wouldn't be drawing much current - USB's limited to 500mA as standard, and my bench power supply didn't show a draw of over 120mA at any point. A perfect candidate for battery power, wouldn't you say? 😈 One less wire / power socket to worry about is always a plus, in PA / live performances...

But first, a small electro-mechanical review of the (stock) unit.

- The five screws holding the two halves of the case together mate with brass threaded inserts - not too shabby for a bottom-of-the-range piece of electronics.

- For extra support, the three pots are all mounted to a metal plate (thin as it may be), which slots into ridges moulded into the top & bottom casing - a nice touch.

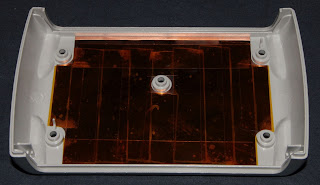

- On the bottom of the PCB, there are several soldermask-less areas, with some conductive foam pads along the rear edge of the unit, which make contact with a layer of copper shielding foil stuck on the inside of the bottom case.

|

| The notations were voltage rails - the mods i made required some reverse-engineering |

- Interestingly enough, the analog circuitry (at least) is supplied via a small SOT23-5 footprint SC1563 very-low-dropout linear regulator.

- The 3.3v digital supply is handled by a generic SOT-223-cased 1117-type LDO linear regulator.

- The brains of the operation is a TI TAS1020B "USB streaming controller".

- AKM converters (AK5365 ADC and AK4381 DAC).

- All the opamps used are National Semiconductor LMV222 dual opamps.

- G-Luxon and Ltec electrolytic capacitors - i've seen way worse, in way more expensive units <cough>CapXon<cough>Scarlett18i20<cough>

- Another appreciated nice touch is the use of a dedicated headphone amplifier / driver chip, namely an NXP TDA1308.

- The two-LED level indicator (Signal / Peak) is made with one half of an LM339 quad comparator. As far as i can tell, the other half (two of the four comparators) isn't used for anything else - they couldn't get any LM393 dual ones cheaper than the quads?

Right, onto the mods. Right off the bat, one small issue - the solitary gain control acts only upon the mic input; the 1/4"-jack line input goes straight into the converter (via an opamp or two). Now, considering most aux / monitor signals used in PA are line-level, "obviously" that would clip the snot out of the mic preamp, even at minimum gain (and there's no switchable pad available).

After lifting the circuit of the mic input stage (a two-opamp instrumentation amp arrangement), i had to fiddle with three resistor values - two in the feedback (which set the minimum gain; 3.42k -> 1k), and one in series with the gain pot wired as a variable resistor (which sets the maximum gain; 20R -> 600-some-odd ohms, i piggy-backed two resistors on top of each other. After that, the following differential amp needed some padding-down as well to get its gain down and its clipping level closer to where the previous preamp clips, so the two series 1k resistors were swapped for two (or three?) 10k resistors piled on top of each other.

|

| No, i couldn't be bothered to "digitize" it - don't judge me! 😁 |

Once that was done too, it turned out i needed to readjust the detection threshold of the level indicators. Stock resistor values are in the top-right of the above hand-drawn schematic. After all the gain-modding, the output of the differential amp starts clipping around 4.2Vpp, and the Peak LED comes up at 4Vpp. Close enough! 😎

And now, on to the power mods. This stage needed some careful planning and a bunch of headscratching, in order to achieve the entire feature list i had in mind:

- I still wanted the unit to function as it did stock, ie. USB-powered.

- I wanted seamless auto-switching between USB and battery power.

- I wanted the charger to be operating whenever the USB was connected (and of course, powered).

- I didn't want the boost circuit (3-4.2v from the cell to the 5v required by the unit) to work when it wasn't operating off the battery.

| ||

| Yes, i digitized this one, because i actually needed to also design as simple a PCB as possible, due to the manufacturing method employed |

The third requirement was quite simple - run a wire from the USB 5v line (before any switching occurs) straight to the input pad of the charger board. Preliminary testing uncovered a quirk: whenever powered from the battery, the red "charging" LED on the charger board lit up. Measurements quickly showed why - even without the USB connected, that floating node got pulled up to roughly the cell voltage.

Once again, choosing the easiest solution, regardless of how ham-fisted it may be, i chose to just whack in a series diode from the USB 5v to the charger input. The reason for this came from a bit of logic, a sprinkle of arithmetic, and the TP4056 datasheet. It's a linear current/voltage regulator, and allegedly uses a P-channel MOSFET as the pass element. As such, even with non-stellar Rds(on) figures, the minimum voltage drop can be squeezed down to maybe a few dozen millivolts. You have 5v coming from the USB, and a fully-charged lithium cell is usually around 4.2v - that gave me about 0.8v of leeway to play with. A jellybean silicon diode drop is in the area of 0.6v. Catch my drift? 😉

Hey - if it's stupid and it works... It ain't stupid! 😎

And whaddya know - no more red "charging" LED lit, while working off the battery 😈 Now, in order to keep things standard-compatible (let's say), i figured i'd drop the maximum charging current down to 3-400mA. With the unit drawing 100-120mA itself, i wanted to stay within the 500mA envelope.

The fourth requirement was really simple and low-tech too. Don't want to run the boost converter all the time while running off the battery? Whack in a switch! 😁

The boost circuitry was simple enough to throw together as well. I had some MC34063 chips left over from an older repair, i threw the calculations from the datasheet / application note into a spreadsheet, juggled some numbers around a bit, and that was that.

|

| The final circuit differs slightly from the schematic - i ended up finding a 15k resistor, so the R4-R5-R6 arrangement got replaced with that |

Just for the hell of it, i used polymer electrolytic caps 😝 Just because i had a couple of them laying around (scavenged a few weeks before, from some dead computer mainboard). A FujiCap / FPcap / Fujitsu(?) 470u/6.3v for the input, and a ChemiCon PSC 270u/16v on the output.

The board layout was a nice little exercise as well. Due to the casing mounting posts, i wanted to make it as narrow as possible, but also with a bit of a length restriction. Also, i wanted to be able to solder the charging board on top of the PCB used for the other two stages of the whole thing, and have them more-or-less feed one into the next, along with some jumper-wires where needed.

And now, finally, a view of the final result:

The 18650 holder is stuck to the top casing with a wide strip of 3M 9087 double-sided tape - sticky / tough as hell). Also, the whole arrangement is juuuuuuuuuust thick enough to allow the case to be closed, with the cell and holder "clamped" in place by the bodies of the front-panel pots. In fact, i even needed to bend a few caps out of the way, and carve off a corner / an edge of the headphone jack's plastic casing. The electronics are affixed to the top case with an M2.5 screw (with a countersunk head, scavenged from some dead laptop - i didn't have long-enough M3's, and they all had thick / bulky heads anyway), a couple of spacer-nuts and a mounting nut.

No rocket science in the front either - just drilled the appropriate-size hole through the metal pot-mounting plate, and subsequently the front panel, and that was that.

Next time, more Li-Ion mods / upgrades, but with a wee bit more mechanical work required...

Hello Khron, i have problems with my M-audio Fastrack USB,

ReplyDeletefirst time, detected as unknown device, and now dead.

can you repair it??..Thanks

awehh1969@gmail.com